Investment Plans Raise the Bar

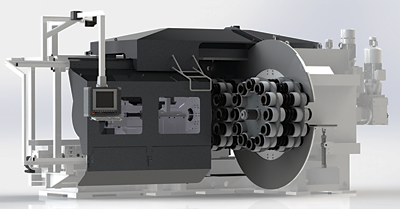

Alloy Wire International (AWI) is currently planning a US$150,000 investment drive that will see the company upgrade its ability to produce wire in straight lengths and bars.

The company, which now exports to over 60 countries worldwide, has seen demand for straight lengths of its round and profile nickel alloy wire grow consistently over the last three years, and is expecting an increase in volumes with aerospace and fastening sectors beginning to recover from the impact of the COVID-19 pandemic.